IT’S A SCENE THAT IS SO AUSTRALIAN.

Deep in the bush amid towering eucalypts, the only noise is the screech of cockatoos and a ground-dweller rustling in the undergrowth. Large kangaroos appear suddenly out of the scrub, bounding across the dirt road. Surely no force other than nature could ever have been at work here.

And then, on the other side of a gully, something catches the eye. It’s a decrepit structure, with one word daubed large in black across its wall: POISON. It’s an old cyanide tank, a reminder that, even though this ageless bush has reclaimed nearly all the surrounding area, it can’t completely eradicate the mad days of the gold rush at Eureka Reef, a seam of quartz mined for more than a century from the 1850s. The reef is a few kilometres south of Chewton, a village outside Castlemaine in central Victoria. What’s left – shafts, tunnels, tailings dumps, dry dams and the foundations of buildings – constitutes just several of the 80,000-plus abandoned mines around Australia.

According to Mohan Yellishetty, associate professor in resources engineering at the Department of Civil Engineering at Monash University in Melbourne, abandoned mines fall under many classifications and definitions. Mining legacies are the umbrella term for previously mined, abandoned (where the owner is unable or unwilling to take remedial action), orphan (the legal owner cannot be traced), derelict or neglected sites. And they vary in size, from vast open-cut pits down to individual shafts a few metres square that still litter goldfields all over Australia.

The Monash team has created a database in a bid to identify, where possible, every mine – active or not – in Australia, a resource Mohan hopes will serve several purposes. Mapping the mines’ locations helps with identifying specific environmental issues relating to the site, and it’s critical to the future planning of communities in areas of significant mining impact.

It should also maintain the focus on the need for proper rehabilitation of the many inactive sites, and Mohan hopes it will help to stimulate the repurposing of old mines in new and exciting ways. “I am a mining engineer and I want to be a proud mining engineer,” Mohan says, “and I can do that by addressing these mining legacies, one of the reasons people curse the industry. They left a lot of these scars.”

Monash had been providing mining companies with point solutions for managing rehabilitation, but Mohan realised there was little geospatial information for mine sites. A GeoScience Australia database was mainly confined to current operational mines. “So I recruited a final-year student to look at Victoria as a case study, and I floated similar projects in Tasmania and New South Wales,” he says. “They had good databases, but what they didn’t have was spatial mapping with good overlays and geographical information systems where you can superimpose mine location data with the likes of sensitive environmental receptors for that state. For example, Tasmania has high rainfall events that could lead to sediments getting into agricultural lands and freshwater streams. Mt Lyell (in Tasmania’s west) could potentially be harbouring a lot of acid sulfate soils from the mine, which would be lethal if they are exposed over long periods. The clean-up costs nationwide would run into billions. We needed an understanding of what exists to be able to suggest remedial strategies to mitigate some of the long-term impacts.”

ONCE MONASH’S DATABASE was completed in 2018, Mohan became more fascinated with the possibilities it opened up. “For example, if there are two pits with an elevation difference, they could be converted into hydro-electricity generation facilities,” he explains.

Specific repurposing depends on each mine, but in general he sees a future for many mines through a resources trinity lens: mine rehabilitation, tailings management and the harvesting of critical metals. The “criticals” get this mining engineer most excited, metals that 15–20 years ago didn’t have high-yield prospects, but which are now vital to the rapid advance of technology. “They have high value when added to some components,” he says, brandishing his smartphone, “and they have high catalytic, metallurgical, nuclear, electrical, magnetic and luminescent properties.”

And it’s not just phones, TVs, renewable energy and infra-red technologies that depend on these metals. “With renewable energy transmission, we’re talking lithium, cobalt, plus rarer metals such as neodymium and praseodymium,” Mohan says. “They are increasingly in demand because much of their current market is controlled by China, which isn’t exporting them.”

Mohan also says a lot of these metals are sitting in the tailings, including with the old standby, gold. “It is a true asset to the nation. Some junior and mid-tier companies asked us for 10 sites where they could reapply for leases. It could be abandoned mines or a tailings storage facility.” Critical minerals aside, Mohan believes having 80,000 inactive mining sites around Australia poses long-term public health risks, with the overarching concern being acid mine drainage. “It’s more or less attached to all the mining sites,” he says.

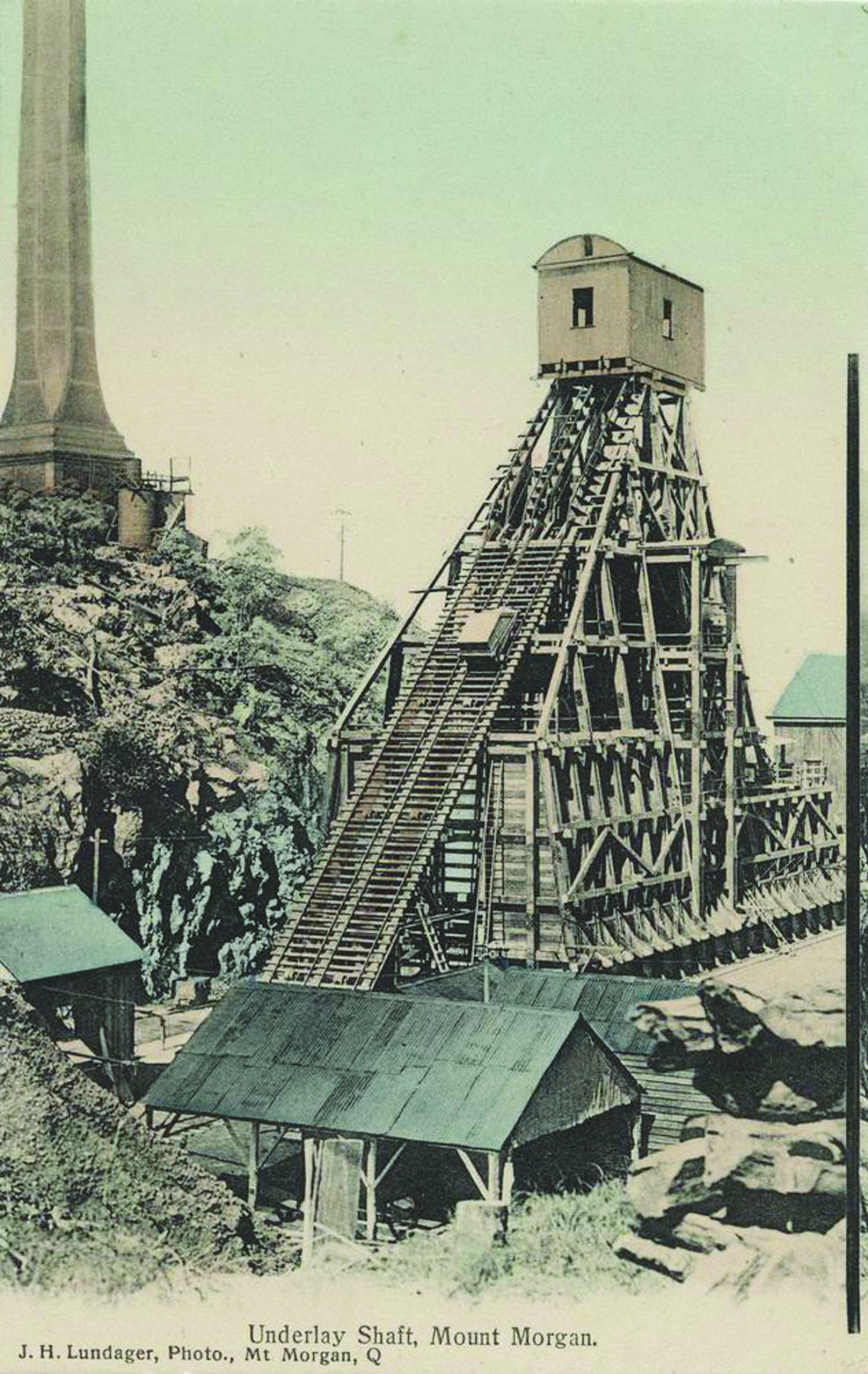

The site is now regarded as Australia’s most polluting mining legacy. Image credit: Alamy

Downstream from the Mount Morgan open-cut gold, silver and copper mine in central Queensland, a sign by the Dee River delivers a stark message: “No swimming, no drinking. Water in this river is acidic.” According to the Mineral Policy Institute, a national body of mining experts and sustainability focused community members, the acid mine drainage (AMD) from Mount Morgan, which operated for 99 years until 1981, is Australia’s largest and most polluting mining legacy. AMD is generated when sulfidic rocks such as pyrite react with water and oxygen in the surface environment, rather than being isolated as crystalline rock underground, to form sulfuric acid. MPI calls this “a deadly toxic soup to aquatic ecosystems and biodiversity”.

Mount Morgan’s unvegetated slag heaps plus the highly acidic pit lake (formed by rainwater) have created an extreme level of pollution, according to Gavin Mudd, associate professor at Melbourne’s RMIT University. “This is a classic case of where industry and government need to show leadership and get on the with job of cleaning it up,” Gavin says, acknowledging the cost would be hundreds of millions of dollars. “This is not the

kind of landscape I want to be seeing in 50 years time.”

Heritage Minerals, a new company, is awaiting final approvals for its plan to reprocess the tailings for gold and copper, starting in 2023. While it’s expected the activity will reduce the level of AMD into the Dee, thus improving water quality – “it’s the only way that we can really solve the ongoing environmental pollution from this site”, says the CEO of Heritage, Malcolm Paterson – the Queensland Department of Resources is responsible for dealing with the legacies outside of Heritage’s operation.

THE MOUNT LYELL copper and goldmine at Queenstown, Tasmania, became notorious for the way it transformed the landscape; tree removal for the smelter, combined with the plant’s discharge, left hills outside town resembling a moonscape. Natural regrowth is restoring the environment, but AMD effects in the river system are ongoing. A potential new owner, New Century Resources, is evaluating what it hopes is a decades-long resource life, but it also needs to allow for remediation. Its managing director Pat Walta told the ABC late last year: “There’s a massive water treatment opportunity there at the very least. We can treat that water and recover those metals…generating value out of that water stream as well. We are going to be studying all the options.”

Remediation is not on the table at Wittenoom in Western Australia’s Pilbara. Once it was understood that crocidolite (blue asbestos) in the tailings at the three asbestos mines was a dire health hazard, abandonment of the mines and town became the only option. But despite about 2000 deaths being attributed to mining activity at Wittenoom, stubborn land-holders have held on, with legislation progressing to compulsorily acquire 14 remaining privately owned properties.

In early 2017, a Senate inquiry heard mining companies were not obliged to reveal projections of costs to rehabilitate mines, and companies could avoid such obligations by going into liquidation. Centre for Mine Site Restoration director Kingsley Dixon told the inquiry the industry was “struggling to find an exemplar among existing restoration efforts”, and while many WA sites could potentially be restored to the level of a functioning ecosystem, some had so dramatically changed the landscape that restoration on that level was impossible.

But substantial restoration efforts have been carried out, including during a mine’s life. Rehabilitation began in what was jarrah forest on Alcoa’s bauxite mine at Jarrahdale, 45km south-east of Perth, several years after it opened

in 1963. It closed in 1998 and in 2001 the company announced the project was complete. Alcoa’s published rehabilitation objective was “to establish a stable, self-regenerating jarrah forest ecosystem, planned to enhance or maintain water, timber, recreation, conservation and/or other nominated forest values”. of Jarrahdale have received Certificates of Acceptance from the state government for significant mining rehabilitation.

At Western No. 5 open-cut mine near Collie in south-western WA, nature dictated the remediation. After it closed in 1997, the water quality in a recreational lake, created when the pit was filled via a channel from the Collie River South, wasn’t good, with pH levels below 4. However, in August 2011 heavy rainfall overtopped the diversion channel, and this flushing improved water quality and ecosystem values. So the river was diverted to its original path, and Lake Kepwari opened for fishing and boating in December 2020.

This (above left) was the site at Coburg in Melbourne’s north in 1955, where bluestone had been quarried for Pentridge Prison. Today is a revegetated lake (right). Image credits: State Library of Victoria (left); Noah Thompson (right).

RECREATIONAL LAKES are a common feature of remediation plans both for large mine pits and small quarries.

Coburg Lake in Melbourne’s northern suburbs was created from the quarry that provided the bluestone for

neighbouring Pentridge Prison, and several new residential developments in Victoria have quarry lakes at their core.

This formula is being writ large at the defunct Hazelwood coalmine, 155km east of Melbourne. The concept for the 4000ha site is centred on a 6 x 4km lake. At the shallower end, a tourism belt would be centred around residential areas, farms, produce outlets and wetlands. The deeper sections of the lake would encompass a productivity hub catering to industrial, energy-producing and agricultural uses.

While mines can be detrimental to the land beyond their basic footprint, work is being done to reverse

the effect: using abandoned pits for flood mitigation, for instance. Dr Peter Bach, who completed his PhD at Monash University in Melbourne, specialises in urban water issues, and his work at the Swiss Federal Institute of Aquatic Science and Technology focuses on modelling of technologies reliant on water (blue) or natural components (green) that can provide a range of ecosystem services. He has identified links with mine rehabilitation.

“If an old mine in a city happens to be in an opportune location, you can build a flood retention system because you already have the ‘hole in the ground’, ‘ in the ground’, Peter says. “That allows you to protect the (current) urbanisation and safeguard future urbanisation. These holes are pretty big and their capacity to buffer heavy rainfall is pretty good.”

THESE SITES CAN ALSO help in improving an urban area’s biodiversity, such as through creating wetlands in quarries. Urbanisation breaks connections that allow animals to move across landscapes, Peter says. “A solution is restoring stepping stones for that movement. Wetlands are the best example in blue-green infrastructure that not only provide pollution removal and stormwater control but also foster bio-diversity. We can look at a system of quarries across an urban area that we can connect as stepping stones for nature, but also for humans – make them bike paths or areas for recreation, for example.”

Mines left as they are can have second lives as tourism experiences, as Central Deborah Gold Mine in Bendigo, Victoria, and the State Coal Mine at Wonthaggi in the state’s southeast testify. But with a lot of the spadework done on underground mines, other uses have been developed, with the Stawell Underground Physics Laboratory (SUPL) almost ready to go.

The facility has been built in a disused tunnel of an active goldmine 1km below Stawell in western Victoria, to search for types of fundamental subatomic particles that may constitute dark matter, the elusive material that makes up 85 per cent of the universe’s mass. “Shielding a dark-matter direct detector from cosmic rays is almost impossible,” says SUPL director Professor Elisabetta Barberio. “However, if the detector is placed deep underground, the material above the detector shields will reduce these rays to a manageable level.” The laboratory cost $11 million; without the tunnels, she says, it would have required hundreds of millions.

The Australian government requires that rehabilitation be woven into any new mine proposal. The Leading Practice Sustainable Development Program for the Mining Industry handbook, published in 2016, states that leading practice rehabilitation starts at the beginning of the project. “Failure to demonstrate a strong commitment to land-use stewardship, particularly successful rehabilitation, can lead to approval delays and, in the worst case, total loss of development opportunities.”

The program contains a clear message that the way in which a mine closure has been effected in the past will influence a company’s continuing ability to operate here. “The industry today recognises that to gain access to future resources, it needs to demonstrate that it can effectively manage and close mines with the support of the communities in which it operates.”

There is consensus here. Mohan Yellishetty says: “Efforts to ensure progressive rehabilitation throughout the life of mining operations are critical for Australia to achieve its goal of being a world leader in environmental stewardship.”

Or as Charles Roche, executive director of the Mineral Policy Institute, puts it: “There are social, political and economic drivers that will continue to create perpetual mining impacts unless we change the way mining is perceived, planned and executed in Australia. Mining legacies need to be addressed at the point of approval, rather than at the end.”