The vast ecosystem of Brisbane’s Moreton Bay contains a multitude of species. There, in the sheltered waters, winding inlets and salt marshes of Quandamooka country, you can find sharks, rays, and hundreds of fish and coral species. Bottlenose and humpback dolphins swim and forage there, as do dugongs and six of the world’s seven species of sea turtle. Meanwhile, the expansive estuary with its shoals, seagrass beds and mangrove forests offers a haven for many endangered species, so you’ll see roosting grounds of far eastern curlews, as well as swamp orchids and ant-blue butterflies. You may even see a southern right whale stopping by. But that’s not all.

If you take a close look along the shores and among the mangroves, says Dr Elvis Okoffo: “You will see a lot of plastic.” Elvis is an environmental scientist at the Queensland Alliance for Environmental Health Sciences at The University of Queensland. He became interested in Moreton Bay a few years ago when he was analysing Brisbane’s wastewater and finding a lot of plastic in the samples. “I started asking myself questions. So, we know there’s plastics in wastewater,” he says. “Where do they go? One of the first things that came to mind was the bay.”

When he and his colleagues analysed dozens of sediments from all over the bay, they were surprised by what they found. “There were plastics in almost every site that we analysed,” Elvis says. Most of it was in the form of microplastics, which are fragments smaller than 5mm in diameter. Based on their data, they estimated about 7000 tonnes of microplastics have accumulated in the bay, which is equivalent to 700 million half-litre plastic bottles.

Moreton Bay is unique in many ways, but not with regard to plastic pollution, which is a global problem. About 20 million tonnes of plastic waste ends up in the environment each year as it continues to infiltrate almost every conceivable ecosystem, from the peaks of the Himalayas to the bottom of the Mariana Trench, which includes the deepest-known point in the ocean. It’s estimated that, by 2050, there will be more plastic in the ocean than fish. So, as a torrent of new plastic joins the profusion of existing plastic waste, it’s easy to feel as though the problem has become insurmountable.

But this is not the case at all. In fact, an emerging ecosystem of solutions offers genuine cause for hope. To really understand the plastics crisis, and how it can be solved, we need to take a closer look at what plastic actually is.

‘Toxic trespass’

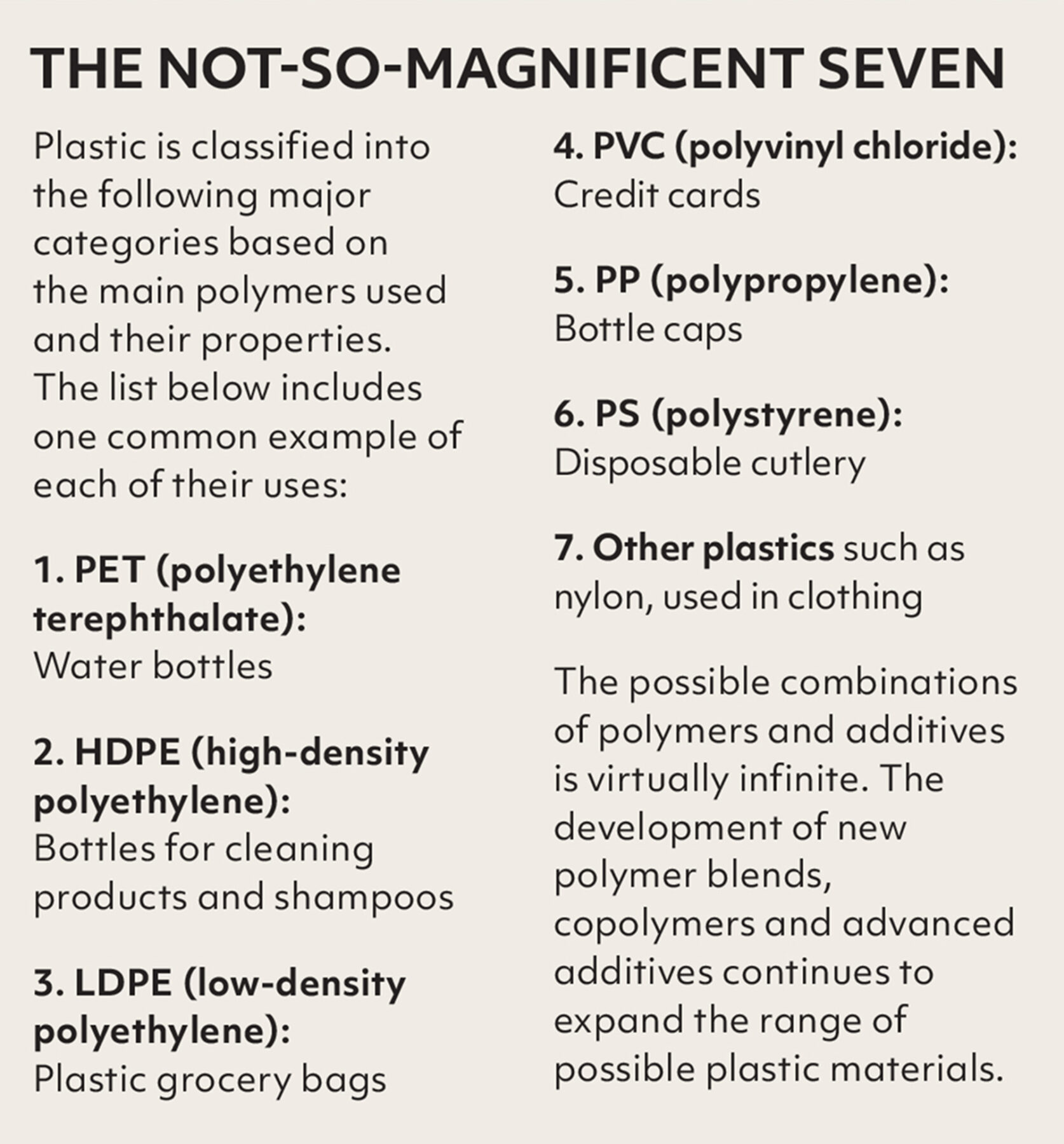

The story of plastics begins with polymers, which are large molecules made of repeating patterns of smaller molecules called monomers. Though some polymers are quite complex, many are just long chains of identical or very similar monomers.

Polymers aren’t inherently bad. The natural world is full of them, from the DNA in every living cell to the keratin found in skin, hair, nails, feathers, wool and more. Complex carbohydrates are polymers, including starch and fibre. Cellulose, which is made by plants and microbes, is the most abundant polymer in the world. But as all these ‘biopolymers’ evolved, so too did biological mechanisms that could break them down, enabling the fundamental building blocks to be reused.

The earliest versions of modern plastics, on the other hand, were invented in the 1800s and involved chemically modifying cellulose from plants. Then, in 1907, the first fully synthetic plastic polymer was made from a mixture of phenol and formaldehyde, and the world hasn’t been the same since. Today, almost all modern plastics are made with synthetic polymers which, in turn, are made of petrochemicals sourced from fossil fuels.

The arrangement of polymers inside plastic is often likened to a bowl of spaghetti and, in keeping with this analogy, ingredients have a big impact on results. The specific monomers used to build a polymer influence its strength and flexibility, as well as how it interacts with other polymers. During production, the addition of chemicals called plasticisers can influence these interactions by encouraging polymers to become more slippery, more tangled, more aligned, more interlinked, and so on. In this way, manufacturers can toggle the flexibility, hardness, durability and density of the final product. This makes plastic an incredibly versatile material with many different uses. It’s also relatively fast and economical to manufacture. Consequently, it has reached almost every aspect of modern life.

“We’re absolutely surrounded by it,” says Emeritus Professor Sarah Dunlop, who leads the Minderoo Foundation’s Plastics and Human Health research program in Perth.

But while plastic is undeniably useful, it poses a lot of health risks. “We really tend to think of plastic as safe, cheap and convenient, but I’m going to argue that it’s none of those things,” she says. Plastics contain “truckloads” of chemicals, she says. In addition to the petrochemical-derived polymers, there are also accelerants and flocking agents, which help build the polymers in the first place. Then you’ve got all those plasticisers, as well as foaming agents, biocides, flame retardants, UV stabilisers and more.

“At last count, there are about 16,000 chemicals used to make plastic,” Sarah says. Moreover, these chemicals are simply mixed in, rather than being strongly bonded to the polymers. Here, she takes the spaghetti analogy a little further: when additives are mixed in, you get something more like spaghetti bolognese. “The plastic chemicals – the bolognese sauce – they’re not stuck to the spaghetti,” she says. This means the chemicals can slowly come out of the products. “They leach into food, water and air.”

From there, it’s a short journey into our bodies where they’re capable of harming our health, even at very low levels. Globally, only a fraction of these chemicals are regulated. “It’s a form of toxic trespass. We didn’t ask for those chemicals to be in us,” she says.

It’s not the only trespass. “[Plastic products] shed little microplastics and even smaller nanoplastics, and this happens every single day when we’re using them,” she says. “Both micro- and nanoplastics are increasingly being reported in human tissue. The smaller they get, the easier it is to get across all these biological barriers.”

Not only are they coming directly from the plastics we use, but we’re also especially vulnerable to microplastics and nanoplastics in the environment.

Plastic pollution

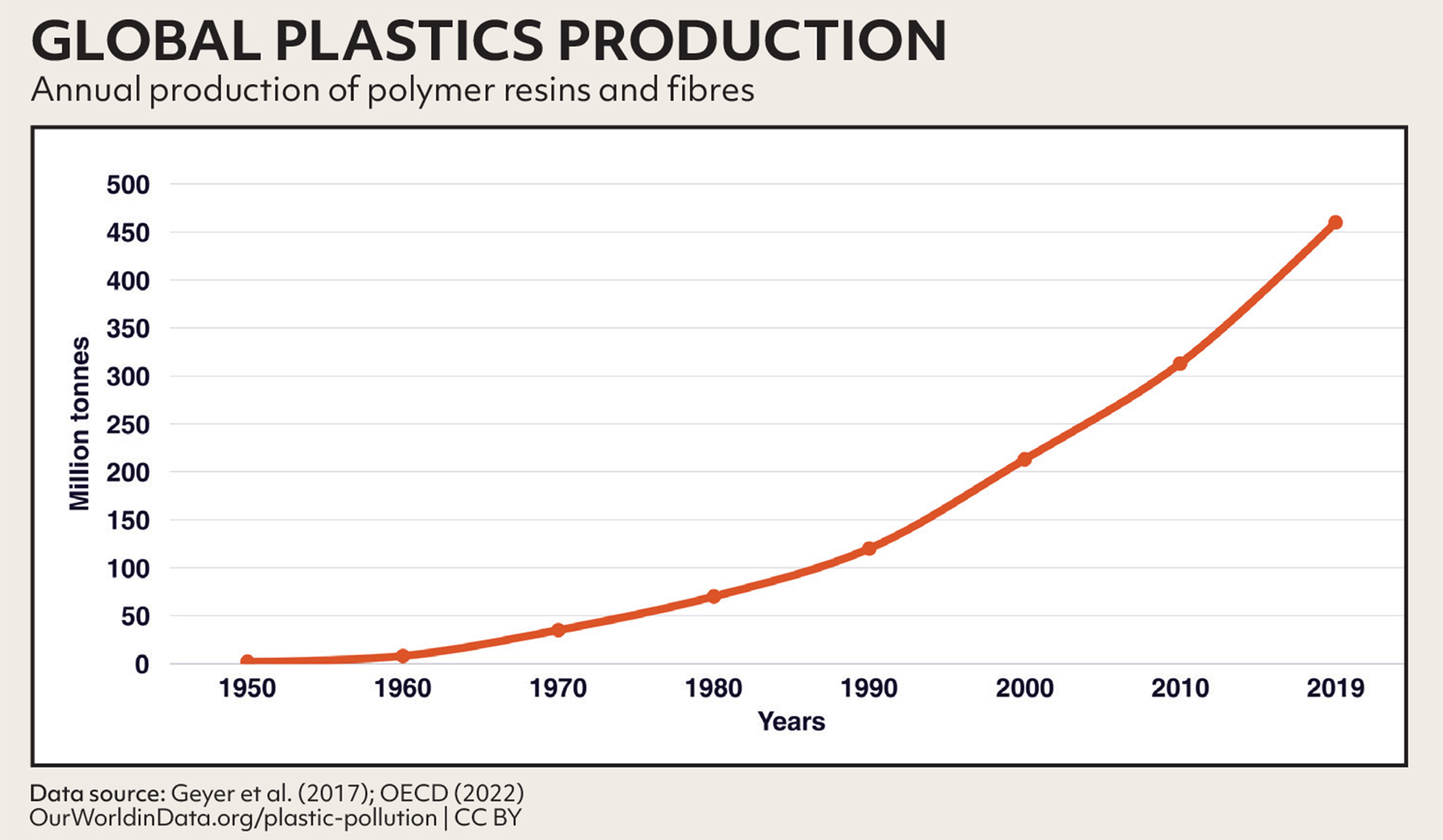

Despite being so useful, most plastic has a bewilderingly brief functional life. Currently, virgin plastic is produced at an astonishing rate of approximately 460 million tonnes per year, and a great deal of that is used in packaging or other single-use applications. In fact, about two-thirds of new plastic is thrown away within a month of being used.

So here we are. Of the estimated 12 billion tonnes of plastic that has ever been made, 70 per cent of it has ended up as waste. And most of it is still out there. This is where its durability ceases to be an attribute and becomes a major flaw, says Dr Deborah Lau, who leads CSIRO’s Ending Plastic Waste program. “[Plastics] are very practical, but they take a very long time to break down in the natural environment,” she says.

For example, high-density polyethylene, which is commonly used in milk bottles, can take anywhere from a few hundred to a few thousand years to degrade. Sooner or later, most of the plastic we discard finds its way into the environment. And although most plastic waste is sent to landfill, it doesn’t really stay there forever. Instead, it degrades over time into increasingly smaller microplastics that can seep into the surrounding soil and groundwater. Then there’s all the unmanaged plastic waste that never reaches landfill in the first place. Recent research from CSIRO shows a great deal of Australia’s unmanaged plastic waste winds up in waterways and coastal areas, especially near urban centres.

When you take a close look at the plastic floating in Sydney Harbour, it doesn’t take long to figure out where it’s coming from. Horrified by the amount of plastic pollution they saw while travelling the world as boatbuilders, Pete Ceglinski and Andrew Turton came up with the design for Seabin. As the name suggests, it’s a bin-like device that you put in the water, which then skims the surface and filters out floating debris. In 2020 they placed several in Sydney Harbour and have since filtered more than 30 billion litres of water and captured more than 22 million plastic items. Some 11 million of those were microplastics.

Identifying the source of plastic pollution is crucial if you want to mitigate it, Pete says, so they analyse the waste they find in the harbour. Turns out, most of it comes from Sydney’s streets.

“We’re starting to see seasonal patterns,” he says. “When Christmas comes around, we start to see more little green fibres or strands, which comes from plastic Christmas trees. New Year’s Eve, we’ll see fireworks and festivity paraphernalia like plastic wristbands. Around Mardi Gras time, we’ll start to see glitter in the harbour. Chinese New Year, we’ll start to see fireworks and little red candies.” When more than 2 million people congregate in Sydney for the annual Vivid festival, plastic pollution rises by up to 200 per cent.

Elvis wasn’t surprised to hear about this and sees similar patterns in his research. “It’s a direct correlation,” he says. “The major plastics that are being consumed in Australia are the major plastics that we see polluting the environment.”

Recycling innovations

The environmental impact of plastic waste has been in the public consciousness for decades. So too has the idea of recycling as a solution. Yet even today, only about 9 per cent of plastic gets recycled.

The reason recycling didn’t save us is because it was never meant to. According to the IUCN’s Centre for Environmental Law, as far back as the 1980s, recycling was largely promoted by members of the plastics and oil industries as a means of assuaging public concern about pollution despite knowing that most plastics are difficult to recycle.

Professor Ali Abbas, a chemical engineer and the director of the Waste Transformation Research Hub at The University of Sydney, explains why plastic recycling is difficult. It’s largely due to the vast array of different types of polymers used in modern plastics. He explains that most recycling systems use mechanical recycling, which physically breaks plastic into smaller and smaller pieces, leaving the polymers mostly intact. These polymers are melted down and made into new plastics. This is fine if you’re only recycling one type of plastic where the polymers are all identical. But if you have a mixture of plastics, you get cross-contamination of different polymers and they won’t bind well together when you try to form new plastic. The resulting material is often weak and difficult to reuse. “It’s very difficult to separate these plastics,” Ali says. “It quickly becomes uneconomical.”

You also lose quality when plastic waste is contaminated by other materials such as paper or food scraps. Sorting and cleaning further drives up costs. Moreover, because polymers degrade with each round of recycling, plastic can only be recycled a few times. In most cases, it’s recycled just once before being sent to landfill.

So, is there any good news? Well, yes. Quite a lot, actually.

First of all, sorting is getting cheaper and more efficient. Recent advancements in this space by CSIRO and others involve the use of robotics and artificial intelligence that can distinguish and separate commingled plastics with high accuracy.

Another option involves getting microorganisms to simply eat plastic. It sounds far-fetched, but there are numerous examples of microbes that have figured out a way to break down synthetic polymers. It’s not as big an evolutionary leap as you might think. Sometimes it’s just a slight change in an enzyme that was already good at breaking down natural polymers.

Ali himself is particularly interested in fungi, which are known for their resilience. “I thought maybe we can explore how fungi could degrade plastics,” he says, explaining that he and his team collected some common backyard fungi and tested it on polypropylene. “Why polypropylene?” he asks rhetorically. “Because [I wanted] a difficult problem to solve! And polypropylene has only a 1 per cent recycling rate.”

Left on its own, polypropylene might take hundreds of years to degrade. But under controlled conditions, the fungi degraded it in a matter of days. When a marine fungi species was tested, it worked even better. Ali says it’s not necessarily simple to scale it up to an industrial level, but it’s certainly possible and something they’re working on.

He envisions biological processes like these being used alongside emerging technologies such as chemical recycling, which can break down certain plastic polymers – like PET or polystyrene – into their original monomers. These monomers are then repolymerised to make new materials and this cycle can be repeated multiple times without sacrificing quality.

Gasification is another option. Plastic waste is heated under specific conditions to produce a synthesis gas – or ‘syngas’ – composed mainly of hydrogen and carbon monoxide. “This gas can be used as a feedstock to produce fuels, chemicals, or even new plastics,” says Ali, who is encouraged by the results so far. “We’re not wasting the plastics anymore; we’re recovering them. The carbon that’s in there, we’re recovering. The hydrogen we’re also recovering, and we’re using that for new pathways to make new products and chemicals.”

Ali applies systems thinking to his work, which involves “looking beyond individual technologies to understand how problems and solutions fit within the larger system – like an ecosystem, where materials, processes and impacts are interconnected.” But because of this interdependence, he says it’s important to anticipate unintended consequences during the design process. Currently, chemical recycling and gasification come with trade-offs, including high energy demands and potential release of greenhouse gases or toxic by-products, depending on the feedstock and conditions. That’s why he and others are working to improve these approaches, both through innovation and by linking them with renewable energy sources or advanced emissions control technologies. If this works, they could have an important role to play in whittling down all our current plastic waste. However, it won’t solve the plastics crisis alone.

“Recycling is dealing with the waste. It doesn’t make a deep cut in the generation of waste,” Ali says. He explains that there needs to be a big shift in thinking, one with far more emphasis on upstream design, including the design of alternative plastics.

“Alternatives will play a huge role,” Sarah says. As far as she’s concerned, if the plastics we encounter on a daily basis continue to be made the same way, then we’re still stuck with all those health risks. “We need a whole rethink of plastic materials,” she adds. The good news is that researchers in Australia and around the world are already fast-tracking the development of safe, alternative materials at scale.

Better plastics and better policies

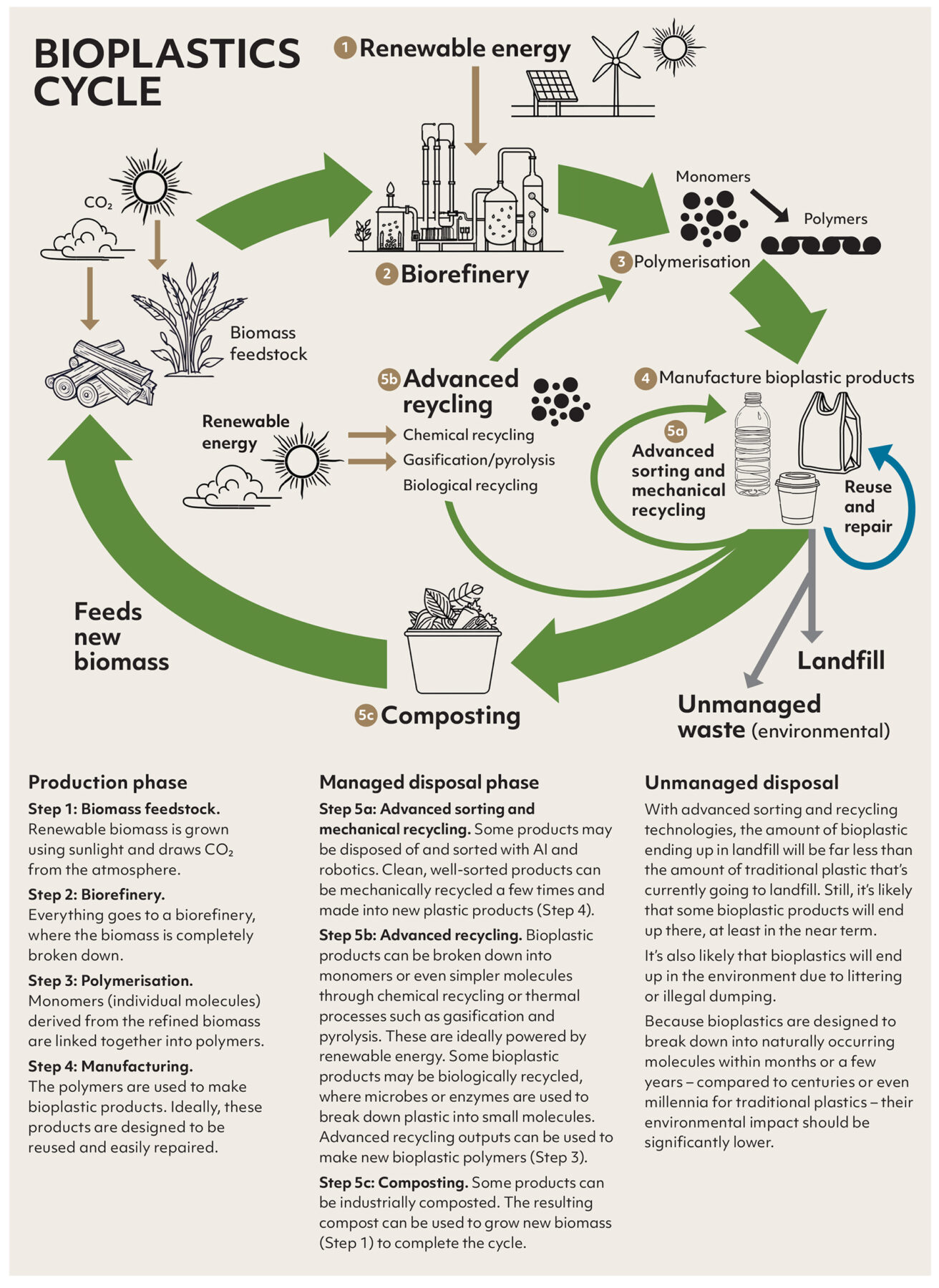

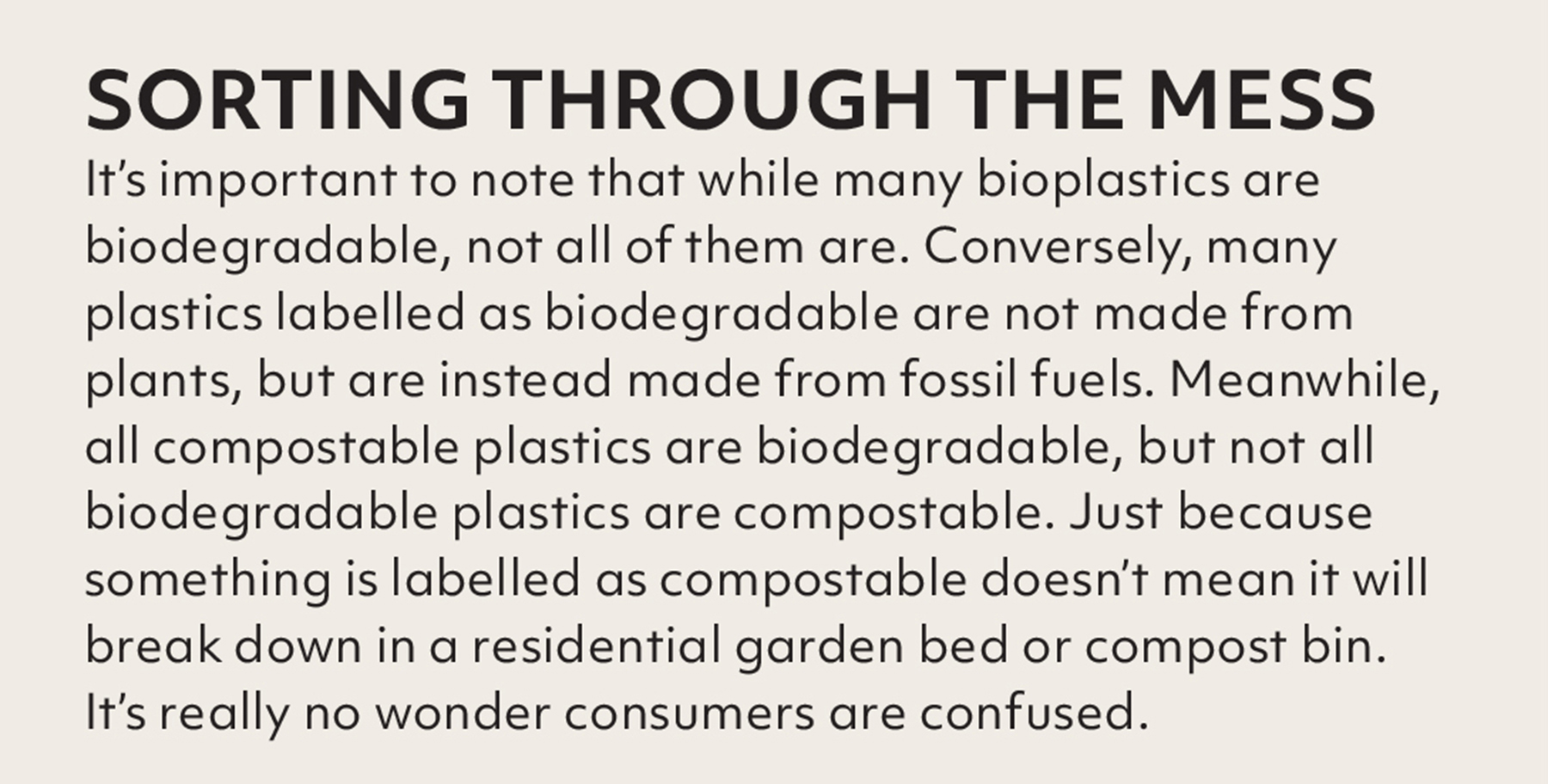

Bioplastics, which are also called bio-derived or bio-based plastics, are made from renewable biomass instead of fossil fuels. Biomass is useful because it contains a lot of starches and sugars, which can be broken down to make new polymers. The feedstock can come in the form of renewable crops such as sugarcane, bamboo, corn, soy, canola, sunflowers and more. It can also be sourced from seaweed, microalgae and wood pulp, not to mention the more than 1 billion tonnes of agricultural and food waste the world produces annually.

Sarah sees a lot of promise in bioplastics. “There are some really good candidates,” she says. “There’s one in particular we’re focused on. It’s a natural polymer that’s made by bacteria. It’s called polyhydroxyalkanoate – PHA for short – and you can get big buckets of bacteria and chuck in anything really: waste sugarcane, waste food, you name it.”

Turns out, bacteria have been gobbling up starch and pooping out natural polyesters (a type of polymer) for billions of years. Now bioengineers and chemists are harnessing this digestive exuberance to produce better plastics. To toggle the physical qualities of PHA polymers you don’t necessarily have to use chemical additives. Instead, you can modify the polymers directly by altering their length or by adding little branches and then tweaking the structure and number of those branches.

Research so far indicates that PHAs are non-toxic, and because of this, they are already being used in a range of medical devices and implants. In fact, production of PHAs is being scaled up for a wide range of commercial uses, with more development underway to both drive down costs and expand potential uses. For example, the Perth-based start-up Uluu uses marine microbes to produce PHA from seaweed that’s both biodegradable and compostable, and because seaweed absorbs a lot of CO2 as it grows, the whole process is carbon negative. Meanwhile, a team of researchers in South Korea just announced they’ve bioengineered microbes to a strong and flexible polymer with similar characteristics to nylon.

Biomass has more to offer than just starches. Fruits and vegetables contain polyols, which are being used in combination with plant-derived lignin to make bio-based polyurethane. Others are making hard bio-polycarbonate from limonene, found in lemon peel, without the need for additives such as BPA.

Bioplastics are a big focus at CSIRO too, Deborah says. On one level, bioplastics will have very similar chemical properties to current plastics. “They will have a similar ability of flexion or movement in the chain that will give them that plasticity,” she explains. “They will quite often be thermoplastic, which means that when we heat them up to a certain temperature, they can be moulded or blown into films.”

So far, only 1 per cent of plastics are made from bioderived sources. But as the technology improves and production costs continue to become more competitive, that number will rise. Deborah isn’t expecting bioplastics to completely replace traditional plastics, though. For now, it’s all about triage, she says. This means identifying which traditional plastics have the worst health and environmental impacts and replacing those with well-designed bioplastics. That means bioplastics will be used in single-use food packaging much sooner than they’re used in, say, durable industrial pumps that can be sustainably recycled.

If we look at this from a systems perspective, as Ali encourages us to do, it’s clear we don’t need anywhere near as much plastic as is currently produced each year. Far more plastic is made than is needed. The shift to bioplastics needs to come alongside a shift in the way we think about and use plastic, as well as a shift in policies. Ali explains it’s not just the materials that need to be circular; business models need to be circular too. The current business model incentivises disposability and overproduction, but this could be shifted by policies that make companies responsible for their products’ downstream impacts.

In other good news, cleantech organisations such as Seabin are eager to continue the clean-up of legacy plastic waste in the environment and expand operations. Pete Ceglinski wants to facilitate the clean-up of coastal waterways in Australia and around the world. They just need the funding.

Seabin Foundation is also focusing on education initiatives to help the public better understand the impact of plastic on the marine environment, how it gets there, and what actions we can take at an individual level and as a community. A broader understanding of our consumption patterns as individuals will be an important part of this, Ali says. This is where sociology and behavioural science can play an important role. Data and digital materials will also help, including QR codes for consumers to scan and read about a product’s carbon footprint, what materials it contains and at what levels, as well as where they came from. “These digital passports are emerging out of Europe and other places, and I believe we’re going to see them [in Australia],” Ali says. “The consumer pull for sustainable products is going to drive the manufacturers to improve everything they do in terms of design and development of these products, logistics of transport of the products to the consumer – all sorts of important things.”

We can be conscious consumers while also using less plastic in general. Elvis says it’s a continuous learning curve, even for researchers: “I didn’t know that plastic kettles release plastic until I started my work, then I just called my wife and said, ‘Hey, let’s just go and change the kettle quickly!’”

So, not only does industry need to make critical changes, but consumers do as well, he says. “I tell people it’s on us. The little things we do play a major role.”

As members of the public, we can advocate for better policies. In 2022 the New South Wales Government introduced a ban on single-use plastic bags, after which Seabin observed a 71 per cent reduction in plastic bags floating in Sydney Harbour. Public campaigns and support played an important role in that, which highlights how collective action can be a powerful magnifier.

Back on Quandamooka country, groups of volunteers have begun gathering regularly to clean up plastic pollution on the shores of Moreton Bay. Among them is Conservation Volunteers Australia. The organisation’s involvement is an expansion of its nationwideSeaToSource project, which aims to not only collect litter but also provide education workshops and citizen science training. It’s open to any members of the public who want to do their part.

Indeed, we have before us a whole ecosystem of solutions – and it contains multitudes.