THE ABILITY TO precisely measure and calibrate things such as time, distance, weight, temperature and brightness has a surprisingly massive impact on our lives. Even seemingly trifling measurement errors can have dire consequences.

Consider, for example, NASA’s Mars Climate Orbiter. This US$125 million robotic spacecraft burnt up as it attempted to enter the Red Planet’s orbit in 1999 because a stuff-up between its navigation software, which used metric units, and its altitude-control system, which used imperial units, placed it 100km closer to Mars than intended.

In France in 2014 another measurement error meant that 2000 new trains, ordered at a cost of €15 billion, were too wide to fit alongside the platforms of many regional rail stations. As a result more than 1000 platforms had to be reconfigured, at vast expense.

Many aspects of ordinary life also rely on precise, standardised measurements. When the alarm on your clock or smartphone goes off in the morning and you navigate your way to work using Google Maps, you trust that time and directional information are accurate. Similarly, when you buy a box of cereal, carton of milk or bunch of grapes, or buy fuel at the bowser, you implicitly trust that the weights or volumes of the goods you’re purchasing are what they claim to be.

Since civilisation began, standardised methods of measurement have been vital for trade and to allow scientific and technological advances, explains Dr Bruce Warrington, CEO and chief metrologist at Australia’s National Measurement Institute (NMI), which is headquartered in the northern Sydney suburb of Lindfield.

“Historically, without a centralised standardisation for weights and measures, you get disputes in trade. You get unscrupulous traders trying to shave a little bit off, or disagreements about whether somebody is getting fair measure, and that goes all the way back to ancient civilisations,” Bruce says. “So it’s always been a job of governments to set that framework in place and to resolve disputes.”

That’s where the NMI comes in. Based across three major laboratory sites in Sydney and Melbourne, and some 20 regional offices with local trade measurement inspectors, the institute is the Australian government’s authority on all things related to measurement. It maintains Australia’s top-level standards across a range of measurements, from time, length and mass to temperature, light, electrical qualities and the composition of chemicals. Most major economies have similar national bodies.

“We rely on measurement for huge amounts of our daily life without even thinking about it. Every time you fill up your car with petrol, every time you buy a kilogram of bananas at the supermarket, it never really occurs to you to check whether that measurement is accurate or reliable,” Bruce says. “You just kind of trust the system, and it’s our job to make sure people can trust that pumps and weighing scales measure correctly.”

The organisation’s scientists ensure measurements are consistent across Australia and the same as measurements internationally. Chemical standards of measurement, for example, enable pollution levels to be monitored for safety in the environment and in agricultural production. They also ensure the accuracy of nutritional content in food, and even the consistent quality of exported resources such as liquid natural gas.

Aside from checking the accuracy of weighing scales, fuel pumps and spirit measures used at pubs, NMI professionals test, calibrate and certify many different kinds of instruments and gauges used right across Australian industry and trade.

“The job of the inspectors is to go out into businesses all across the country – pubs, petrol stations, supermarkets, small traders and businesses – to check how well that system is working,” Bruce explains. “They’re not there solely to wield a big stick. A big part of their role is education, making sure people know their obligations and how they can meet them.”

The NMI tends to target particular industries at different times. In April 2019, for example, it audited 1340 petrol bowsers in 328 service stations and other fuel sellers across Australia. Nine retailers were found to have ‘under-pouring’ pumps that were short-changing customers. Between them they were fined a total of $15,750.

“Most people don’t even think about whether the amount of money they’re paying is giving them the right number of litres. But we think about it,” says Dr Barry Inglis, Australia’s first chief metrologist (before Bruce) and, until recently, the president of the Paris-based International Committee for Weights and Measures. “We think about it because we’ve got inspectors that go out to service stations and we’ll check the quantity.”

Like something from a ’70s sci-fi movie

The NMI’S sprawling Lindfield campus, in bushland on Sydney’s North Shore, is packed with nerdy delights. Here a plethora of devices and facilities is devoted to testing every kind of measurement imaginable. For example, stacked over three storeys, the deadweight force machine is used to calibrate gadgets that measure serious weights and pressures.

“We calibrate instruments to the highest standards and precision in Australia,” says NMI scientist Dr Mark Tucker, pointing to a compact black device squished within the machine and that belongs to one of the airlines. It will later be used to calibrate scales that weigh aeroplanes. The deadweight force machine, which uses steel weights to apply up to 55 tonnes, also calibrates instruments that commercial companies or universities might later use in stress tests of samples of concrete or steel to find out, for example, how strong and durable they are.

“It starts here and then one instrument that we calibrate might then be used for verifying hundreds of instruments in laboratories around Australia,” Mark says. “There are other labs that do similar things, but not to this precision and not over this range of forces.”

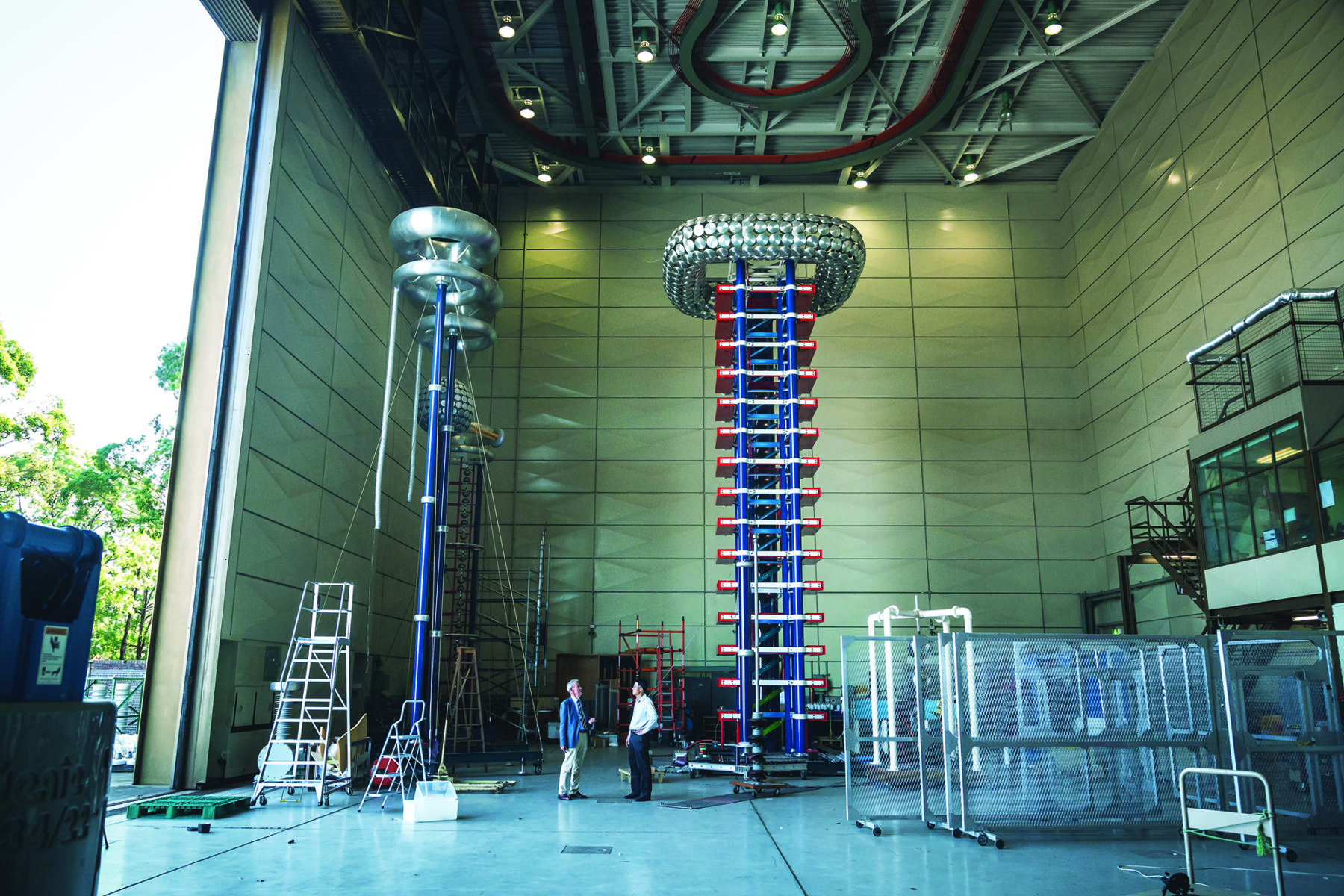

A short stroll away is a building that houses the NMI’s high-voltage laboratory, which can produce some of the biggest voltages in Australia. Like something from a ’70s sci-fi movie, the lab has a number of towers that look like giant colourful lollipops, some with great big metallic donuts on top.

The high-voltage impulse generator can produce artificial lightning strikes to test equipment that will become part of the electricity grid. For electricity networks to be reliable, high-voltage power equipment must be able to withstand lightning strikes, so it’s tested with artificially generated lighting, says the lab’s manager, Dr Yi Li.

“We maintain the national standards for the electricity supply industry. Transformers, insulators and measurement devices have to be tested to make sure they function correctly,” Li explains. “This is the only laboratory that can be used for testing this equipment. It also maintains the primary measurement standards for all electrical power and energy sold throughout Australia.”

Other facilities at Lindfield test the brightness of lasers and ultraviolet lamps used in laboratories and hospitals, to make sure they are safe. They even confirm that traffic lights are bright enough to be seen in direct sunlight. “We do everything from realising the definition of the candela [the unit for luminous intensity] and then converting that into things like the brightness of UV lamps used for sterilisation or for the treatment of jaundice,” Bruce says. There’s also a purpose-built microscope that can measure distances down to about one 10 thousandth the width of a human hair. “We use a very fancy laser system that has a calibrated wavelength, which you can think of as a very fine-grained ruler,” Bruce adds.

One of the many crucial roles performed by the NMI’s Flow Measurement Facility at Londonderry, in western Sydney, is the calibration of meters used in the oil and gas industry to test the flow of petrol, diesel and LNG. As well as physical testing facilities, there are labs that test chemical properties too, some of which are based at another site in Sydney’s North Ryde.

One of the NMI’s more unusual jobs is to test lottery balls to ensure they are all precisely the same weight. “We actually write a certificate that says we’ve checked these lottery balls and there’s no bias in their mass,” Bruce says. The NMI also analyses athletes’ samples to detect banned substances that could give them an unfair advantage. Its Australian Sports Drug Testing Laboratory – the only lab in Oceania accredited by the World Anti-Doping Agency – is based at North Ryde. It performs most of the drug testing in sport in Australia and New Zealand.

Working right at the very cutting edge, NMI scientists are developing techniques to detect so-called gene doping. This involves the illegal transfer of genes or genetically modified cells into an athlete for the purpose of enhancing their performance.

In the food sector, the NMI helps make sure products labelled as allergen- or gluten-free really are what they say they are, and that products such as Manuka honey actually contain what they claim to contain. “Is it really Manuka honey, or has it had a cheaper honey or corn syrup added and it’s being passed off as something that’s higher value?” Bruce says. The honey attracts a premium price because of claims that it has therapeutic values. In 2016 the NMI established a chemical fingerprint for

Manuka honey as part of a major study for the government of New Zealand, which is a major exporter of the product.

The definition of the seven units of measurement change

On 20 May last year, a quiet revolution in measurement science took place. The date 20 May was already of great importance among NMI scientists, because it marks World Metrology Day.

But last year it held special significance, because that’s when the definition of the seven units of measurement that provide the basis for the International System of Units (SI) were all finally changed from being based on Earth-bound references – such as a platinum-iridium reference for a kilogram that is locked in a French vault – to definitions based on universal physical constants, such as the speed of light, the electric charge of an electron and the Planck- or Boltzmann constants.

The decision that led to this was taken by delegates from 60 member states at the General Conference on Weights and Measures (CGPM) in 2018, and was the realisation of a dream first mooted 150 years ago: a system of measurement based purely on unwavering, fundamental properties of nature.

The experimental work that made redefinition of all base units possible took more than 40 years, explains Barry Inglis, who is now retired but remains an Honorary Fellow of the NMI. Barry was director of CSIRO’s National Measurement Laboratory from 1994 until his 2004 appointment as the NMI’s first CEO and chief metrologist. He retired from that position in 2011. He was, however, also president of the Paris-based

International Committee for Weights and Measures (CIPM) from 2011 until 2019, when he presided over the change to the newly defined metric system.

“At the meeting where the decision of redefinition was finally taken, there was such jubilation,” Barry recalls. “You can imagine the relief and joy of finally accepting this as the basis for our international measurement system. We had tears in our eyes.”

The journey to having ever more precise and standardised units of measurement goes all the way back to ancient civilisations, which created measures of length based on human arms, feet and hands, and measures of mass based on the weights of seeds from crops such as wheat, barley and carob (see the timeline below).

“A bunch of those early distance or mass units goes back to the properties of the pharaoh or the king,” Bruce explains. In ancient Egypt the cubit was the length of the pharaoh’s forearm, from the tip of the forefinger to the elbow, while in the year 1130, English king Henry I decreed that a yard was the distance from the thumb on his outstretched arm to the end of his nose.

The change last year was the biggest in measurement science since the French metric system was adopted by 17 nations that were signatories to the Metre Convention in 1875.

That defined the metre as one 10-millionth of the distance from the North Pole to the Equator, and the kilogram as the mass of 1L of water.

“[Before this], in France, there were something like 2000 different measurement systems. Just about every village had its own measure of length and volume,” Barry explains. “So think about trying to trade even just between different villages and you’ve got big problems.”

Bruce adds: “In the 18th century, trade became increasingly international, and there was a greater focus on needing sound measurement to underpin technological innovation.”

A growing desire for more rigorous scientific methods of quantifying the world led to the official implementation of the imperial system (feet, pounds and inches) across the British Empire in 1824, and then, in 1875, the metric system across most major western economies. (Only three nations today have not adopted the metric system in their civil life: Myanmar, Liberia and the USA, which, have therefore humorously been dubbed by one journalist as the “Axis of Medieval”.)

After the adoption of the metric system, the Bureau of Weights and Measures (BIPM) in Paris set about keeping units consistent by creating physical reference objects to which everything else could be compared. This led to the International Prototype of the Metre and International Prototype of the Kilogram, forged from decay-resistant platinum-iridium alloy and safely secured in a vault south-west of Paris.

Roughly the size of a prayer candle, the kilogram came to be known as ‘Le Grand K’ or ‘Big K’ and is so precious it has only been handled once every 40 years or so. Copies are held by all BIPM member states. Australia’s is at Lindfield.

“We have Australia’s copy of the international prototype kilogram here in a safe. It’s still the base of our Australian mass scale. We use it to calibrate a whole lot of working standards all the way down a big chain that ultimately goes out into industry,” Bruce says.

One of the driving factors for last year’s redefinition of the SI base units was that the mass of Big K has, for unknown reasons, been very slowly and slightly diverging from the mass of the copies held around the world. The differences are tiny (just 50 micrograms, or about the weight of an eyelash), but even this matters when masses must be precisely calibrated.

“We don’t really know why the kilograms are diverging,” Barry says. “One possibility is that there might have been some gas that was trapped in the castings when they were made and there’s been slight diffusion through the crystal lattice. But the fact that they’re changing with respect to each other is a problem.”

Redefinitions have occurred in the past. In 1967, rather than being linked to the movement of the Earth, which also changes over time, the second was redefined in reference to the fixed energy gap between two states of the caesium-133 atom, which matches a frequency of 9,192,631,770 cycles per second. Then, in 1983, the metre was redefined in reference to light speed, as the distance travelled by light in a vacuum in 1/299,792,458 of a second. It was inevitable that the definition of the other five base units followed suit and were redefined in reference to physical constants too.

These changes are not something most of us will notice in our daily lives. “This is not going to impact on the amount of potatoes you buy,” Barry says. But it will allow for future technological advancements in fields as varied as genetics and nanotechnology. Nearly every major technology you could name today, from spacecraft, GPS and the internet to smartphones, solar panels and high-speed trains, would not be possible without highly accurate methods of measuring and quantifying things.

“We can now have confidence in the long-term stability and security of our measurement system,” Barry says. “If you have a kilogram weight sitting in a vault in Paris, you potentially have problems if something happens to it. But now, in principle, these units can be realised anywhere by anyone.”

What exciting scientific advances might the changes to SI measurements allow? It’s difficult to predict just yet, but every time civilisations have increased the precision and conformity of its measurements, new technologies have emerged.

“The better you can measure, the better you can build something new, like a pyramid or an aircraft,” Bruce says. “Investing in measurement and measurement science is a great way of helping to drive broader technological development and economic advantage.”